Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register now7 Secrets of the Best Industrial Printer Machine You Never Knew

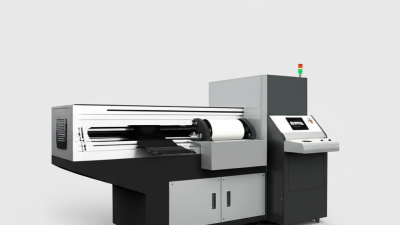

In today's fast-paced manufacturing landscape, the demand for efficiency and precision has made the choice of an Industrial Printer Machine crucial for businesses aiming to enhance their operations. According to a recent report by Smithers Pira, the global industrial printing market is projected to reach $244 billion by 2024, driven by advancements in technology and an increasing need for customized printing solutions.

Various types of industrial printers, from inkjet to laser systems, each offer unique features tailored to specific product requirements and applications. Understanding these differences is vital for companies looking to optimize their printing processes and achieve superior results.

This blog will uncover seven secrets about the best industrial printer machines that you may not be aware of, providing insights into their characteristics and suitable applications across diverse industries.

The Importance of Print Resolution in Industrial Printers

Print resolution is a critical factor that significantly impacts the quality and efficacy of printing in industrial settings. In the realm of industrial printers, resolution is measured in dots per inch (DPI), and higher DPI values typically indicate finer detail and sharper images. The importance of high print resolution cannot be overstated, as it directly influences the legibility of barcodes, the vibrancy of colors, and the overall fidelity of printed materials. Manufacturers, requiring precise output, often depend on high-resolution printers to ensure each label and packaging component is accurate and visually appealing.

Moreover, high print resolution plays a vital role in reducing waste and improving production efficiency. With better quality prints, the risk of errors decreases, which means fewer reprints are necessary. This not only saves time but also slashes costs associated with materials and labor. In industries where branding and presentation are paramount, investing in a printer that offers superior print resolution can set a product apart in a crowded marketplace, ensuring that every detail is rendered flawlessly and adheres to industry standards. As such, understanding and prioritizing print resolution is essential for businesses seeking to enhance their printing processes and achieve outstanding results.

Importance of Print Resolution in Industrial Printers

Understanding the Various Types of Industrial Printer Technologies

Industrial printing technologies have evolved significantly, with various types playing crucial roles in diverse applications. Among them, 3D printing stands out as a transformative force within manufacturing ecosystems. By layering materials to create intricate designs, 3D printing not only streamlines production processes but also blurs the boundaries between traditional manufacturing sectors. Its ability to rapidly prototype parts and components is reshaping how industries approach product development and customization.

Moreover, the rise of industrial inkjet printers is another key development in the realm of industrial printing. The global market for these printers is projected to reach impressive figures, underscoring their importance in high-volume production environments. This technology enables precision and flexibility, essential for businesses aiming to enhance efficiency while maintaining high-quality output. As manufacturers continue to explore innovative printing methodologies—from additive manufacturing to advanced inkjet technologies—the landscape of industrial production is set for a dynamic transformation. The interplay between these technologies not only fosters competitive advantages but also encourages the growth of new manufacturing paradigms.

7 Secrets of the Best Industrial Printer Machine You Never Knew

| Printer Type | Technology | Print Speed (ppm) | Max Resolution (dpi) | Typical Applications |

|---|---|---|---|---|

| Inkjet | Thermal or Piezoelectric | 30-150 | 1200 x 1200 | Labels, Packaging |

| Laser | Electrophotographic | 40-120 | 2400 x 2400 | Business Documents, Labels |

| Thermal Transfer | Direct or Indirect | 30-90 | 600 x 600 | Barcodes, Asset Labels |

| Dye Sublimation | Sublimation Transfer | 10-30 | 300 x 300 | Textiles, Photography |

| 3D Printers | FDM, SLA | Varies widely | Varies widely | Prototyping, Custom Parts |

| Large Format Printers | Inkjet, Solvent | 20-50 | 1200 x 1200 | Banners, Posters |

| Jetting Technologies | Continuous Inkjet, Drop-On-Demand | Varies widely | Varies widely | Industrial Marking, Coding |

Key Features to Look for in High-Performance Industrial Printers

In the rapidly advancing world of 3D printing, understanding the key features of high-performance industrial printers is crucial for businesses aiming to stay competitive. Recent advancements reveal that materials such as metal and composite structures have become the trending focus, thanks to their superior mechanical properties including rigidity and lightweight characteristics. According to a 2022 report on China's 3D printing industry, these materials offer significant advantages over traditional options, highlighting a shift towards more advanced manufacturing solutions.

Moreover, innovations in printing technology, particularly in the development of high-entropy alloys with exceptional strength and ductility, are paving the way for new applications in sectors like aerospace and healthcare. A team of researchers successfully printed a dual-phase nano-structured alloy, showcasing strength and flexibility that surpasses existing capabilities. This breakthrough illustrates the continuous evolution of 3D printing technology, emphasizing the importance of investing in industrial printers that can leverage such advanced materials and processes for enhanced performance and efficiency. As companies navigate this dynamic landscape, selecting the right features in industrial printers will be key to unlocking future growth and innovation.

How Maintenance Practices Can Extend Your Printer's Lifespan

Maintenance practices play a crucial role in extending the lifespan of industrial printer machines. According to a report from IndustryWeek, regular maintenance can increase equipment longevity by up to 40%. This is particularly vital in the printing industry, where downtime can lead to significant losses in productivity and revenue. Simple practices such as cleaning print heads, regularly replacing worn-out parts, and monitoring ink levels can prevent extensive wear and tear. Such proactive measures not only enhance printer performance but also ensure consistent print quality, which is essential for maintaining client satisfaction.

Moreover, implementing a scheduled maintenance plan can significantly reduce unexpected breakdowns. A study conducted by the National Association of Printing Users highlights that 67% of printer failures are attributed to improper maintenance. By adhering to a routine check-up schedule, businesses can avoid costly repairs and extend the equipment's operational life. Investing in staff training to recognize early warning signs of printer malfunctions further supports longevity, as informed employees are more likely to carry out preventative measures that can save organizations thousands of dollars in potential losses.

Cost-Effective Strategies for Reducing Ink and Material Waste

When operating an industrial printer, cost-effectiveness is crucial, especially regarding ink and material waste. Implementing strategies to minimize these expenditures not only boosts your bottom line but also enhances your overall operational efficiency. One effective tip is regularly maintaining your printer. Keeping print heads clean and ensuring nozzles aren’t clogged can lead to clearer prints with less ink usage. Additionally, programming the printer to run at optimal speeds can reduce wear and improve ink efficiency, making every drop count.

Another strategy is to leverage the printing software's settings. Utilize features like draft mode for less critical prints, which consumes less ink, or select the right paper types that complement the printer's capabilities. Matching the ink to the media can drastically reduce waste and improve print quality. Furthermore, conducting a thorough analysis of print jobs can help identify patterns and optimize production schedules to avoid unnecessary prints, thereby conserving materials in the long run. Embracing these strategies will make a significant difference in how your industrial printer operates, ultimately leading to reduced costs and increased productivity.