Partner Login

Enter your username and password here on order to log in on the partner portal:

No registered partner yet?

Register nowInnovative Examples of Inkjet Coder Applications Driving Efficiency in Modern Manufacturing

In today's fast-paced manufacturing environment, efficiency is paramount, and innovative technologies are at the forefront of driving productivity. One such technology making waves is the Inkjet Coder, which has transformed the way products are marked, labeled, and tracked across various industries. By integrating digital solutions and advanced coding techniques, manufacturers can enhance operational effectiveness, reduce waste, and ensure compliance with regulatory standards.

In today's fast-paced manufacturing environment, efficiency is paramount, and innovative technologies are at the forefront of driving productivity. One such technology making waves is the Inkjet Coder, which has transformed the way products are marked, labeled, and tracked across various industries. By integrating digital solutions and advanced coding techniques, manufacturers can enhance operational effectiveness, reduce waste, and ensure compliance with regulatory standards.

This blog will explore several innovative examples of Inkjet Coder applications that not only streamline production processes but also empower companies to adapt to the ever-evolving market demands. From enhancing traceability in supply chains to enabling real-time data capture, the examples discussed will illustrate how Inkjet Coders are becoming indispensable tools in modern manufacturing, merging technology with efficiency to create a robust framework for success.

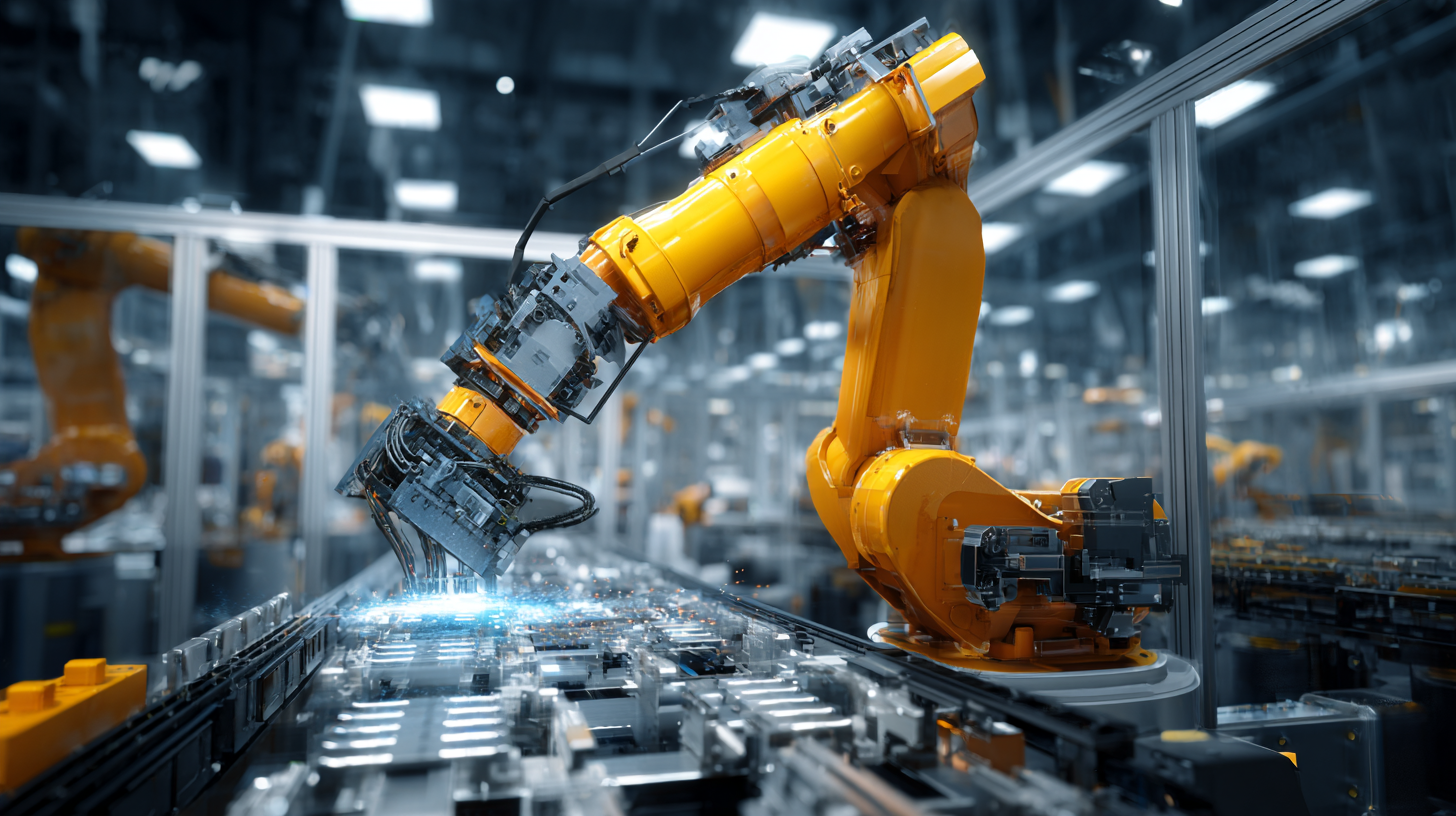

Innovative Inkjet Coder Technologies Revolutionizing Production Lines

In the ever-evolving landscape of modern manufacturing, innovative inkjet coder technologies are playing a pivotal role in transforming production lines. These advanced coding solutions enhance efficiency by enabling high-speed marking and printing without compromising on quality. With the ability to easily adapt to various substrates and integrate seamlessly with existing systems, inkjet coders facilitate real-time data tracking and product identification, which are essential for maintaining rigorous supply chain standards.

The integration of inkjet coders with robotic systems further amplifies their impact on production efficiency. As industries increasingly rely on automation, the combination of inkjet technologies with robotics allows for precise coding and labeling at unprecedented speeds. This not only improves operational throughput but also minimizes errors in product information, which is critical in sectors such as food, pharmaceuticals, and consumer goods. As manufacturers seek to optimize their processes, these innovative inkjet coding solutions stand out as indispensable tools driving modernization in production lines.

Enhancing Product Traceability with Advanced Inkjet Coding

In today's fast-paced manufacturing environment, advanced inkjet coding technology is playing a crucial role in enhancing product traceability. Businesses across various sectors are adopting this innovative approach to ensure that every item on the production line is easily identifiable and trackable from production through to the end consumer. This process not only helps companies maintain high standards of quality control but also enables quick responses to potential recalls or safety concerns.

The integration of inkjet coders facilitates the printing of essential information such as batch numbers, expiration dates, and QR codes directly onto products and packaging. These high-resolution printouts allow for seamless data collection, ensuring that manufacturers can trace the origin and journey of their products with accuracy. Furthermore, the use of unique identifiers aids regulatory compliance, fosters customer trust, and helps in gathering valuable insights into production processes. As manufacturing technologies continue to evolve, leveraging inkjet coding will remain vital in promoting transparency and efficiency in supply chains.

| Application Area | Efficiency Improvement (%) | Traceability Features | Cost Reduction (%) |

|---|---|---|---|

| Food and Beverage | 15 | Batch Number, Expiration Date | 10 |

| Pharmaceuticals | 20 | Serial Number, QR Codes | 15 |

| Cosmetics | 18 | Expiration Date, Manufacturing Location | 12 |

| Electronics | 25 | Date Code, Compliance Information | 20 |

| Automotive | 22 | VIN, Production Date | 18 |

Reducing Downtime: The Role of Inkjet Coders in Maintenance Efficiency

In modern manufacturing, minimizing downtime is crucial for maximizing productivity and cost efficiency.

Inkjet coders play a pivotal role in this aspect, providing reliable and quick solutions for marking and coding products without causing interruptions to the production line.

These advanced coding systems not only ensure compliance with regulations but also enhance the overall traceability of products, which is vital in today's fast-paced supply chains.

Inkjet coders play a pivotal role in this aspect, providing reliable and quick solutions for marking and coding products without causing interruptions to the production line.

These advanced coding systems not only ensure compliance with regulations but also enhance the overall traceability of products, which is vital in today's fast-paced supply chains.

To effectively incorporate inkjet coders into maintenance processes, manufacturers should consider implementing regular training sessions for their operators. Familiarizing them with troubleshooting techniques can significantly reduce response times during unforeseen downtimes. Additionally, maintaining an inventory of essential parts for the inkjet systems can expedite repair processes, ensuring that production halts are kept to a minimum.

Another important tip is to schedule routine checks of the inkjet coders. Proactive maintenance can catch potential issues before they escalate, allowing manufacturers to replace worn components during scheduled downtimes instead of facing unplanned halts. By prioritizing these practices, manufacturers can leverage inkjet coders not just as marking tools, but as strategic assets in their maintenance efficiency strategies.

Streamlining Packaging Processes through Inkjet Coder Integration

The integration of inkjet coders into packaging processes is revolutionizing modern manufacturing, enhancing efficiency and precision. These advanced coding systems can print high-quality codes, barcodes, and logos directly onto packaging materials, eliminating the need for labels or secondary printing processes. This not only reduces material costs but also accelerates production speeds as products move seamlessly along the assembly line.

Moreover, inkjet coders are remarkably versatile, capable of adapting to a range of packaging types—from flexible pouches to rigid containers. This adaptability allows manufacturers to implement a streamlined approach, ensuring that every package is accurately marked with the necessary information without interrupting the workflow. With real-time data integration, manufacturers can easily track production metrics, maintain compliance with industry regulations, and respond to market demands with agility, ultimately leading to a more efficient operation.

Driving Sustainability in Manufacturing with Eco-Friendly Inkjet Solutions

In the realm of modern manufacturing, eco-friendly inkjet solutions are emerging as a crucial component in driving sustainability. Traditional marking solutions often rely on solvents and chemicals that can be harmful to the environment. However, innovative inkjet coding technologies are transforming the industry by utilizing bio-based inks and water-soluble formulations that reduce toxic emissions and waste. This shift not only aligns with global sustainability goals but also helps manufacturers comply with increasingly stringent environmental regulations.

Moreover, these advanced inkjet systems enhance operational efficiency while minimizing environmental impact. By integrating digital printing technologies, manufacturers can achieve precise coding with minimal ink waste, significantly reducing their carbon footprint. Additionally, the flexibility of inkjet coding allows for on-demand production and customization, supporting efforts to reduce overstock and excess materials that often end up in landfills. As manufacturers embrace these eco-friendly inkjet solutions, they position themselves as leaders in sustainable practices, demonstrating that environmental responsibility and operational excellence can go hand in hand.